|

|

|

Canít warn those pesky SUV's to stay away from your beloved MGB? Your problem could be in the steering column contacts. Mine was. If you havenít had your columnís plastic surround pieces off then you may be able to repair your non-working or intermittent horn without a lot of trouble. This is for the later year chrome bumper B's from about 1970 and up but the technique should be the same for other years. If your toots feebly or sporadically when you press the horn button then more than likely itís a horn button - horn brush contact problem. The horn works by grounding a purple/black wire at the steering wheel. The purple/blackís 12vdc is carried through the harness to a brass spring finger contact inside the plastic column surround pieces. This finger contact rides on a brass ring on the back of the steering wheel hub so it can make continuous contact when the steering wheel is turning. The horn brush pencil mounts in a hole in the hub and touches the other side of the brass ring on one end and the horn button on the other. When you press the horn button it grounds the horn brush pencil and toots the horn. Itís pretty simple, really. First, pull off the horn button. You can then see the horn brush pencil sticking up out of the hub. Take your voltmeter ( you do have a voltmeter donít you?) and test the brass end of the pencil to see if you have 12vdc. If you do, then rotate the steering wheel to several different positions and re-test. If you lose the 12vdc then proceed. If you donít then the problem may be in the horn button itself, another easy fix. Weíre going to assume you donít have the 12vdc. Grab the horn brush pencil and pull it out of the hub paying attention to which end goes into the hub. Test it with your ohmmeter to make sure itís got good continuity and the wire inside isnít broken. Pull the steering wheel off. You can do this by loosening the nut on the steering shaft and rocking the wheel back and forth while you pull out. Leave the nut on until you get the hub worked loose from the steering shaft. You may have to pound the end of the shaft with a rubber hammer while pulling upwards on the wheel. If you donít leave the nut on, the wheel will suddenly come loose and whack you silly. When you regain consciousness, we can proceed Now that you have the steering wheel/hub off turn it over so you can see the brass ring on the bottom we were talking about.

Now look

down inside the plastic column surround and you can see the brass spring

finger contact that rides on the brass ring. It should all make sense now

that you can see it. Test the brass spring finger for 12vdc. If itís

there, then proceed. If not, you have purple/black wire problems.

In any

case, now that you have the wheel off you might as well take care of these

contacts, since youíve done the hard part. Turn the wheel right side up and look inside. Youíll see two Phillips (Pozi-Drive) screws that secure the brass ringís plastic holder. Take them out and the brass ring holder assembly will come right off.

You clearly see the spot at the top where the horn brush makes contact. It is corroded and cruddy and the poor contact has caused heating. You can see where the plastic has slightly melted.

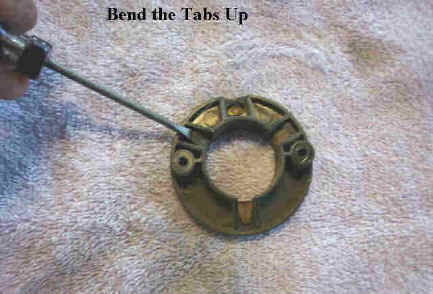

Bend the three tabs up with a small screwdriver. You may want to use a set of needle nose pliers to bend them the rest of the way. You only need to get them up enough to pop the brass ring out. Theyíre pretty stiff and seem easy to work with.

Once the brass ring pops out hereís what you have. The burnt spot is evident.

Take some fine (800-1000 grit) sandpaper or your Dremel tool with a wire brush and clean an area between two of the tabs. You're going to rotate the brass ring so you donít use the burnt area so just clean up another area about midway between two tabs and towards the outside of the ring. Turn the ring over and clean the other side. The finger will be riding around the entire circumference of that side. Smear a little dialectic grease on the ring if you have any. Pop the ring back on the holder making sure you turned it so the new spot is under the brush pencil hole.

Bend the tabs back over with the small slotted screwdriver, and youíre back in business. Put the plastic holder back on the hub, making sure that the brush pencil hole in the holder lines up with the hole in the hub. The hole is at the bottom of this picture.

Re-install the wheel/hub back on the steering column and put the brush pencil back in. Test it for 12vdc. If you had 12vdc at the finger in the column you should now have it at the end of the brush pencil. Put the horn button back on, making sure to line up the hole in the buttonís back plate with the brush pencil. The hole has a thin brass plate in the bottom thatís easy to see. The horn will toot when you are putting the button back on. Test the horn by tooting it a number of times, or until you better half comes out to see what Ďtells going on. Then you can act like you did something really complex. ďYah, had to tear it down and refurbish it so the horn would work, you know us MG folks - ĎSafety Fastí

|