BACKGROUND:

When

we retired from the Army in 1993, we built our retirement home outside Gurley,

Alabama where I also built my dream garage. The garage was designed with enough space for all the cars I

envisioned owning--at least, all the cars I envisioned at that particular moment

in time. Naturally, Shannon and I called it theAutoist"

garage; Jerri just called it my "Garage-mahal".

|

theAutoist garage

was originally a 28'x54' structure with a second story

and a full 20'x20' workshop (woodworking area, engine build

room, etc.). It has western cedar siding and looks like our

house, and has a small porch outside the workshop and a 4 foot roof

overhang in front of the 3 Clopay cedar overhead doors.

Its heated & cooled with a 3-ton heat pump.

My one concession to Jerri was a 20'x8' area behind the

workshop. It houses the stairs to the 2nd floor

and a long pantry where she stores all her food.

Jerri likes to keep lots of things on hand in case of an

emergency. She also has an extra refrigerator and

a freezer in that area. And its where we plan to

put a half bath in the future.

So, I actually had 34'x28' dedicated for car storage.

For Christmas last year, Jerri gave me a small TV and

Dish satellite setup for my workshop. For my

birthday, Shannon & her husband, Jeff, gave me a

small refrigerator. And, since then, I've bought

another, larger, flat screen TV for the garage

itself. In addition, it has a complete stereo

system to include a Pioneer receiver and Bose

speakers. Thus, Jerri's name: Garage-mahal

And, in the 10 years since I built it, it has quickly become too

small for my car collection. The main reason

it's too small is that my collection has grown

drastically. Since we built the garage, I've

developed a new goal: to own 1 of every model MG built after

WWII (I don't know why!). Right now, there are 16 MG's

that are permanent residents.

|

|

And, we also built a separate little garage (16'x32') next to the Garage-mahal

to house our odd cars:

Shannon's '71 Karmann Ghia, Jerri's '73 VW Bug, and my Mercedes

380SL. The photo to the right was taken just as we were installing the

roof, before we started thinking about siding. Still, today, my 2 pickups

and Jerri's C280 still sit outside in the weather!

|

|

THE

BUILDING PLAN:

|

I'm finishing the interior of the garage a little

differently than most garages. The bottom 4'

of the walls are corrugated steel. Above that is

2' of white peg board that I'm using as display areas

for some of my parts collection. Above that is 4'

of whitewashed paneling. That will be finished off

with a 5" crown mold tying into the ceiling that

will also be painted white. Its a slow process

that I work on as I get time. The floors will

receive some type of epoxy paint. And I'm slowly

adding my old automobile signage - along with some new

reproduction signs and my license plate collection; and,

yes, I do have an old Alaska license plate! |

|

|

|

|

|

|

|

An

example of the interior

along with my MG steering wheel collection |

The main

wall separating the workshop from the garage & my MG

wire wheel collection. Yep, that's a Norton in front of my

stand-up air compressor! |

The back

wall leading outside to our smaller garage & the

outside stairs to the 2nd floor. |

My small

cleaning/sandblasting room and MG steel wheel collection. |

I finally convinced Jerri to allow me to add onto the Garage-mahal

(She says it looks more like a house than a garage

anyway so, why not; well, that's what I wanted: a house for my MG's!). So, we

recently began construction on a 20'x44' solid glass

addition on the rear that can't be

seen from the street. That makes the entire garage 54'x48', and space

is already at a premium!

A local apartment complex was

remodeling and was replacing all its

sliding glass doors. I bought them and am using

them for windows on 2 walls of the addition. And,

while the front half (or the original structure) has a

10'4" ceiling height, the addition has an inside clear ceiling height is 12'4", plenty of

space for a 4-post lift. Here's a photo of the

rear of our house with the garage attached to it.

|

|

That apartment complex was also

remodeling its kitchens so I bought their old cabinets

to use in my 20'x20' workshop and in other places around the

garage (like in my sand blast/parts wash area). Under them, I built sturdy work

benches. Oh, on some of the cabinets I left the doors; on others I

removed them. In the center of the workshop I've a

large table saw that sees double duty as a heavy work

bench. And as you can barely see in the photo,

I've a dust collection system built in. |

|

|

|

|

|

|

Work

shop wall holding stereo & drill press work

station. |

Workshop

back wall, part 1. |

Workshop

back wall, part 2. |

Work

shop wall with refrigerator & work area. |

|

|

|

|

Oh,

here's a photo of my Whirlpool fridge.

Notice the built-in cutting board on top of it. |

As part of the new addition, I'm also adding a 4-post lift.

To gain access to it, I've installed a sliding garage door in

one corner of the new addition. Earlier, I had

removed one of my Clopay overhead garage doors - a cedar one -

when I enclosed the small area it opened into to use as a

sandblast/tool wash area. So, I decided to turn that door

into a sliding one and use for this purpose. It was quite

easy, actually. I just bought barn door hardware and

replaced the folding hinges of the door with metal straps.

So, here's the installed lift. Its a Garage Master 7000N

I purchased through

Metro Lifts

& Equipment

in Mobile, AL

(1-888-661-5454). We had to

move the off-side ramp inwards about 5" so both Midgets and

MGB's fit.

My 1974 round wheel arch Midget is on the

lift.

My 1968 MGC & 1963 MGB are under it. Both were painted

about 3 years ago & no rust has returned so they're ready

for restoration.

Over the last few days, I've been working around the garage,

finishing off the tin and paneling installation, and installing

a drop ceiling. At the

same time time, I'm also beginning the trim work. Here are

some updated photos:

Oh, what's in my garage today?

|

|

|

|

|

|

1963 MG

Midget |

1979

MGB |

L

to R:

1956 MG Magnette

1960 Farina Magnette |

L

to R: 1963 MG1100

1953 MG TD, 1959 MGA,

1968 MGC, 1963 MGB,

1974 MG Midget (on lift) |

|

|

|

|

L

to R: 1976 MG Midget,

1979 MGB, 1967 MGB GT, 1968 MGB GT |

1970

MGB GT |

1974-1/2

MGB GT |

1972

Norton |

Well, work progresses and I realized I've not

kept pace here. The drop ceiling is in the front half,

paneling is going up, and lighting is coming together. Soon,

I'll crank up the 3-ton central heat pump to provide air

conditioning and heat on demand - after I insulate the back

half. But, here are some progress photos.

|

|

|

|

|

|

|

Front Porch

Here's where I'm going for the old gas station theme. |

How do ya

like that lighted Texaco sign? |

|

|

Dropped

ceiling & permanent lights in front half of

garage. The section that is wood will be painted

white. |

Oh, did you see my winter

restoration project in the last photo? A 1958 A. O. Smith

gas pump!

PHASE IV: Yesterday, we poured the slab for the next

phase of construction. Initially, we built a 28x54

garage. Then we built a smaller 18x32 shed off to one end of

the garage. Next, we added a 20x44 glassed showroom onto the

rear of the original structure. This 16x32 slab bridges the

area between the smaller garage 'shed' and the main structure.

|

|

The slab

consists of 2 different areas; the back half is smooth and

will be enclosed to make our new "Midget

Room". The front half is brushed and will be an

open-air pad where I can either work on cars or store my

trailer. There's a 3' down-turn incorporated into

the slab with a smoothed edge so it blends into the slab. |

|

|

The small

'bumped out' section will be demolished and will be the

main entry into the new addition. Inside it has a 9'

opening that will remain. Also, the door will be

removed and turned into a cased opening. The bottom

3 steps to the second floor of the original garage will be

turned around so the wall can be extended outward where

the support post stands. Once the 'bumped out'

section is removed, the new area to be enclosed will be

21' wide plus the 18' of the small shed garage and 16'

deep with 9' overhead garage doors in the front and rear

wall |

Let the destruction begin!

11

May 2006:

Gotta

put a date here to keep things straight.

Since we took the first photo of the new slab, we're gotten

pretty far in the build. The front and rear walls

connecting the large garage with the little garage shed are

finished.

|

|

To

accommodate the front wall, we had to redo the stairs

leading to the second floor. That front wall has an

opening for a 9' overhead door. It also separates

the small garage shed into two sections: one that will be

inside the garage itself and one that opens onto the

covered outside pad to hold my lawnmowers and yard

equipment. |

|

|

The rear wall also has an opening for an overhead door

opposite the one in the front wall along with an opening

for a 3' door. It also has openings for a couple of

the sliding door "windows" used across the rear

of the main garage. |

|

|

And, except for the roof, the small 'bumped out' section

of the garage where my parts washer and and blaster were

located is now gone. We'll remove the roof when

we've decided how to frame the new addition's roof. |

Next is the roof. We'll extend the roof of the

little shed garage up and out to the garage itself, covering the

addition. The trusses arrive next week.

Before they can be erected, we have to remove the old roof that

extends out from the original garage and build a fake wall

alongside the original garage wall to support them.

Demolition

of the final part of the existing garage to be removed is finished! The

new "Midget Room" s ready for its roof. We

went...

And my custom-built trusses arrived today; so, after I lay out

the roof plan, we start setting them in place.

We have a roof! One good, long Saturday:

|

|

|

|

|

|

Looking

up through the trusses |

Laying

the strand board |

Almost

here! |

Finished! |

|

|

|

|

Front |

Rear |

Now that the trusses and strand board are up, its rolling out

the felt in preparation for shingles, building overhangs, facia

and sofit in the rear, and extending the front roof to cover the

outside work area. Plus, the gables have to be

closed in.

WHEW!

|

|

Well, this is

where she'll languish for the next month: black paper is

on the roof, windows are installed, and the rear gable is

ready for trim work. When I next work on the

project, I'll focus on cornice work on this gable/wall,

getting it ready for overhead door and small people door.

Then, I'll turn my

attention to building the front carport area. |

15

July 2006: Now

that I'm back in town, things are progressing slowly. The

back wall is ready for trim and cedar siding and the rafters are

up for the front open carport section. The front wall of the

addition is also ready for its siding; but, I've not yet figured

out what I want to use there..

|

|

|

|

Front |

Rear |

24

July 2006: The roof decking on the front carport/outside

work area along with its black

paper is finished and now I'm working on the finish work for the

front facia.

|

|

|

|

Here's

the carport/outside work area with its

rafters, decking,& black paper... |

...and

this is what it looks like with

the header & OSB sheathing installed. |

5

August 2006:

|

|

I've added a small overhang to the front of the carport

over the opening to provide some protection from blowing

rain. I checked and my Mercedes 380SL fits underneath perfectly

with room to spare where the overhead door of the Midget Room will

be, and with

plenty of room on both sides to open both its doors.

When we start

finishing

the inside of the Midget Room and carport will be figuring out a beam system for an overhead engine

hoist in the carport.

|

|

|

I also did

some measuring and found that I can extend the main garage

roof

and enclose the stairs to the second story landing.

That will entail building a knee wall at the front edge of

the landing in the photo to the left, extending the second

floor landing sofit out about 3 feet, and building a gable

wall sitting on the header beam for the carport. Its gonna

be a little tricky tying it all together; but, I'm really

excited about that project! |

9

September 2006: It may not seem

like I've done much lately; however, everything's been going on

behind the scenes. We redid some fencing in the rear of

the garage to open up an area so I can drive straight through

the new addition to get to my side overhead door.

|

|

The front of

the carport area is taking shape with shingles on the

overhang and the beginning of facia and soffit work. |

|

|

Out back, I'm

framing up a small lean-to shed as storage for my

lawnmower and associated tools. That'll free up an

area inside the new addition for my 3 German cars. I

couldn't start this little project until I removed a 20'

Bradford Pear tree and moved the fencing around. |

23

September 2006: Unfortunately,

I neglected to take any photos as I finished the little lawnmower

shed; however, its complete and ready for siding. I also

moved some of the fencing that separates our lawn from Jerri's

raised bed garden, orchard, and grape arbors (as well as my MG

parts storage buildings). That new fence allows me to bring

cars straight through the new "Midget Room" to the side

door of the main building where the 4-post lift is

located.

Then, this last week, was

spent installing the facia and soffit of the main showroom garage

as well as OSB between all the tall windows.

After that was finished, we switched back to the new construction

area (lawnmower shed & Midget Room) and tackled the soffit,

facia, and siding. For this new part of the Garage-Mahal, we

decided to use a different siding that would complement the cedar

siding on the main building while breaking it up. We found a

barn siding that comes in 4x8 sheets and installed it. Then,

all corners, facia, and edging was done in rough cedar like the

main building.

A little side bar: The lawnmower shed was built around my

favorite fig tree. The tree came from one that's been

growing in Mississippi at one of my elderly aunt's home for well

over a hundred years. Confederate soldiers picked figs from

it during periods of rest between battles. One day when I

was visiting her, I mentioned how much I had enjoyed those figs as

a youngster - man, they are sweet. Well, she grabbed a

garden tool and whacked a shoot out of the ground. I've

placed it in several locations around my property but where it is

now is the only place it liked enough to grow and bear

fruit. Hopefully, the shed will provide additional

protection to ensure it continues to flourish. (I know, you

didn't care - but I do!)

|

|

We also

tackled the driveway out front. I say

"driveway" but its really just a 12' x 16' pad

in front of our privacy fence that transitions our gravel

parking area to the street. I really like the large

gravel parking area in front of the Garage-Mahal, but I

didn't like how the gravel was always migrating out into

the street. So, we laid a pad of brick pavers from

the street to the fence around our parking area.

Next, we'll plant some evergreen shrubbery on either side

of the pad. |

28

September 2003:

The front of my outside work area is finished, the front wall of

the stair enclosure is ready for rafters, and the back of the

showroom is coming along. Today we added the Western Cedar

around the windows in preparation for the cedar siding.

|

|

|

|

The wall

between the new addition

and the original garage is where

we're extending the roofline to

enclose the stairs to the

2nd floor. |

You want

windows?

I've got windows!

Western rough cut cedar is

being installed as frames around them. |

30

September 2006:

|

|

WHEW!

Today we got the stair enclosure finished. That was

fun, matching the 10/12 pitch of the original roof.

Now its time to lay the shingles since all the new

construction is complete. |

7

October 2006:

We've spent the last week putting shingles on the roof (except for

the stair enclosure), and we've finished the cornice work on the

new construction. We also added a window to the 2nd floor

stair landing. All the cedar is around the showroom windows

and the seamless 46' gutter along the rear of the main garage is

finished.

Plus, we've started on the rough electric work in the Midget room;

ceiling light boxes are installed along with some of the wall

outlet boxes.

13

October 2006:

|

|

Shingles are

on; only trimming them is left. Now, we're finishing

the soffits on the new addition and starting the cedar

siding installation. The plan is for the garage to

look finished from the road by the end of the weekend. |

And we're continuing on rough electric work inside at the same

time. Plus, we'll be building a couple of temporary walls so

we can remove the wall between the original structure and the

Midget Room. To do that, we have to build a new header

capable of supporting the end of the original garage and the

trusses of the addition.

22

October 2006:

The siding is almost finished all around the outside and we're

moving inside. Here are updated exterior photos"

|

|

|

|

|

|

|

Rear of

the main "showroom" with its cedar siding. |

New 2nd

floor stair enclosure getting aged cedar siding so it

matches original. |

Front of

addition is finished. |

The front

of my workshop is beginning to take on a country gas

station look. |

Front of

garage except for the shed hidden by cedar trees. |

Inside, we've finished the rough electric and started installation

of the hard insulation on the Midget Room along with strand board

ceiling and wall coverings; and we've cut a huge 14' opening

through the wall between the new Midget Room and the original

garage.

25

October 2006:

|

|

My newest toy

for the GarageMahal: an old Tireflator!

We're gonna paint it

Texaco green and, in the Spring, run a hard air line to it

so its operable! Neat, huh? |

8

November 2006:

Finally! Except for staining, the exterior of the

GarageMahal is finished! We're now working on the interior

of the addition plus I've been working in the "command

center" which is now equipped with a computer linked to the

internet, copy/fax machine, and telephone.

|

|

|

|

|

|

theAutoist

Shipping & Receiving |

Workshop |

Workshop |

Workshop |

|

|

|

|

|

|

|

Entrance

to

Workshop |

New

Addition

Carport |

New

Addition

Small Shed & Stair Enclosure |

Rear of

Garage |

Corner

Where Garage

Connects to Breezeway |

Ain't she purty?

Landscaping is going in, we're working on Jerri's outside kitchen

that's on the breezeway, and generally turning our focus to the interior.

2

January 2007:

As I said: interior! The back half of the "Midget

Room" is finished and occupied (there's still some

straightening up needed). The bottom half of the walls are

corrugated tin, and the upper part is white peg board with

paneling overhead.

|

|

|

|

|

Tain't

they pretty?

Both little Midgets have their factory hardtops in place.

And I can walk around them! |

This view

gives an angle on the work area with my work bench, parts

cleaner, and sand blast cabinet.

There's actually room! |

Close up

of my work area

(yes, I know the bench is cluttered. But now I can

finally get to it to straighten up!) |

Now we turn to the interior of the "center room" that

will house my '53 Midget, my '53 TD, and my motorcycle.

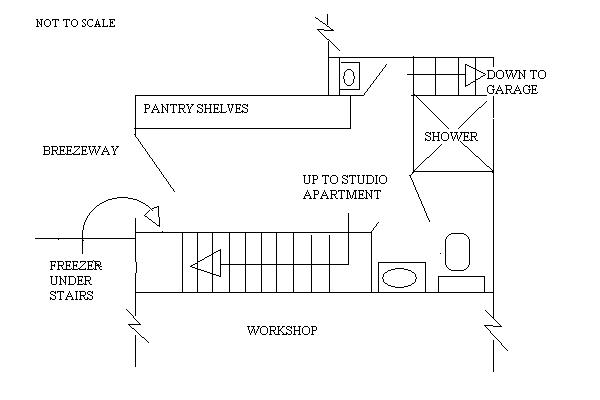

4

January 2007:

Here's a sketch (not to scale) of the footprint of the GarageMahal:

14

January 2007:

Finally! The interior of the 'Midget Room' and 'Center Room'

complete. All that's left is for the roll-up doors to be

installed and the trim painted. Painting the trim will come when the weather turns warmer. The roll-up doors are

ordered and will be installed when they arrive.

|

|

|

|

|

|

Looking

into the 'Center Room'

with the 'midget Room' behind.

The blue tarp on the left and large opening on the right

are where the roll-up doors go. |

Motorcycle

storage area in the

'Center Room'. The large opening on the left is

there a roll-up door goes to separate the 'Center Room'

from the 'German Room'. |

Rear wall

of the 'Center Room' with its large windows opening to the

South., the small door opening to the back yard, and the

blue tarp where a roll-up door will go. |

Looking

into the 'Center Room' from the 'Main Showroom' shows the

wall we opened to build the addition and the dropped

ceiling we have to redo. |

17

March 2007: It

seems as though its been a long time since I've gotten anything

done; and it has. I was out of town the entire month of

February so work came to a halt. During that lull, however,

my roll-up doors were made and delivered. Yesterday, we got

them installed. Lemme tell you, roll-up doors are easy to

install! Now we can lock the garage and set the alarm.

|

|

|

|

|

|

|

The front

door under the carport from the carport side. |

View of

that door from outside the carport. German car

parking is to the right in the little shed. |

Inside of

the front door. The off-white color really matches

the paneling. |

The rear

door from the outside. That 2' overhang will protect

it from the elements. |

Inside

view of the rear door. There's construction stuff

stacked everywhere right now! |

Because I chose to put the doors on the outside of the garage so

the huge roll wouldn't take up ceiling space inside, I now have to

go back and pour a 4" wide concrete lip at the rear

door. I may just concrete the entire 20-or-so-foot square

area around the rear of the new roll-up door and the sliding door

to my 4-post lift; less grass to cut that way!

Now I've got to clean up after all the construction and put away

the lot of parts I recently purchased from a garage that went out

of business. Man, there's stuff stacked everywhere.

Seems no matter how big this garage gets, there's still stuff

everywhere!. 28

April 2007:. I

hate leaves! Especially when they blow through my open

garage doors. Well, I recently found a web site that solved

my leaf problem: Kitty

Mac Fresh Air Screens.

One half hour per door and no more leaves, insects or stray birds

inside my garage. And they don't block any sunlight or

darken the garage at all. I can roll them up to drive in or

out and unzip one side to walk through. Man, where have

these things been all my life!!

|

|

|

|

|

Screen

door down |

Screen

door rolled up |

One side

of screen door unzipped. |

Installation is so easy anybody can do it. Each door comes

with a roll of self adhesive hook and loop material long

enough to go down both door jambs and across the door

header. After its stuck to the door jamb, attach the screen

to the jamb and put roofing nails (I used sheetrock screws

with the roofing nail plastic squares) through the screen where

the straps are attached. Then, simply attach the screen door

to the hook and loop along both jambs. Finally, insert a

piece of 3/4" plastic electrical conduit through the pouch

swen in the bottom of the door to weight it down and make it easy

to roll up and secure to the straps at the op of the door.

VOILA! Screen door!

|

And we also

finished the gutters and landscaping around the rear of

the Garage

Mahal. Jerri even pitched in and added some color

with lots of rose bushes in front of the evergreen

soon-to-be short hedge. The building finally blends

into the entire lawn. |

21

July 2007:

|

|

While we were

in Europe this summer, we noticed that many buildings had

some type vine growing over their fronts. We've wanted

to develop a European flavor for the GarageMahal and liked

that idea; so, I just finished building a trellis (guess

that's what its called) across the

3 main overhead doors over which Jerri is growing

Wisteria. She had planted the Wisteria before we left

on our vacation and it was reaching the roof so I had to

jump right on the construction. She thinks by this time next year it will

have grown all the way across the front of the garage

providing shade and also softening the face of the building. |

Fall

2007: We've

had a crew of painters over for 6 weeks redoing everything, the

house & garage. They pressure washed everything, replaced

cracked cedar boards, caulked, primed and painted. The place

is now Hunter Green. Here's a few photos.

|

|

|

|

|

|

|

|

Right View |

Rear of

Garage |

Rear of House |

Left View of

House |

Front of

House |

Front Door |

|

|

|

|

Left View

of Garage |

Front of

Garage |

And while we had crews at the hose, we removed all the screening

from the dining and sleeping porches, laid tile floors and will redo

the screening next summer.

14

September 2008:

I found these lights on sale at Hobby Lobby for $10 apiece so

I got enough to go all the way around my shop. And, the

diamond tuft plug strips came from Lowe's; they're all around the

shop also.

2

December 2008: A

friend who lives in Connecticut recently installed a solar heater

panel on his garage, and told me about it and how much it helped

with the inside temperature of his workshop. He got the idea

from Mother Earth News magazine. You can read the

article he sent me here.

The rear of my garage is a bank of windows made from siding door

panels which will be perfect for solar heaters.

|

There are 14

windows along my south-facing wall. My plan is to use

the center 2 windows for a solar heater and then use every

other one from those two out to the corner windows for

additional solar heaters. That way, I'll still have 7

open windows to allow the light into the garage. One

modification from the way the article says to build the

heaters is that I'm going to use my sliding glass door panels

instead of the clear corrugated polycarbonate panels. I

also do not want to open my garage up to the outdoors while

I'm building the solar heaters. |

| Step 1 is

to prepare the interior side of the south-facing wall so that

I can later go outside and build the solar heaters without

affecting my garage's interior space. Since each of my

solar heaters will be 28"x82", I cut

4"x14" vents at the top and bottom of the 5/8"

fiber blackboard that will be the back of my

collector. The magazine article explains the

placement of the vents. Then, I painted the blackboard

with some flat black paint. Yes, I know the blackboard

is already black from the manufacturer; but, it has white

writing stamped on it & the original black paint doesn't

permeate the board itself. Next, I temporarily

stood the blackboard in the window frame, holding it in place

with tiny strips of wood. On to the other windows that

will become solar heaters. |

|

More steps to

come..... 16

December 2008: Had

to put the solar heater project on hold for a few days. Some

time ago, I told a very good local contractor who primarily does

renovations of 'antique' houses that when he got caught up and

had some free time, we wanted him to finish an upstairs 20x20 game

room we had designed into the original GarageMahal

construction. We also wanted him to finish Jerri's 8x16

pantry, the stairs going to the 2nd floor and build a half bath on

the pantry level. All something we've had in the back of our

minds since I started building 15 years ago! Well,

last week he called and said he and his sheetrock guys wanted to

stop by to look the job over. He's too good to miss out on so

when he came over, we talked, ironed out details

and they began insulating yesterday. One change we made

while he was here is that Jerri wants a small apartment-sized

kitchenette (stove, microwave, sink, refrigerator). So that's

been incorporated into the plan and all the wiring done for it as well as

for the TV I

wanted. Photos

of our progress to date:

|

|

|

|

|

|

|

|

Looking up

the

stairs from the

pantry area |

Part of game

room

where sheetrock

is hung |

Crew figuring

out

one of the many

ceiling angles |

The large

cathedral dormer |

Wall where

the kitchenette will go |

Looking down

into the

pantry area at the roughed-in 1/2 bath |

Part of the construction was some destruction, especially in the

pantry and 1/2 bath area. The last photo above shows the area

where much of that destruction is occurring and where some of my

earlier mistakes are being corrected. Once the entire

project is complete it'll also be where we house my HO train setup.

I'm thinking my grandson will soon take over this 'attic nook'.

22

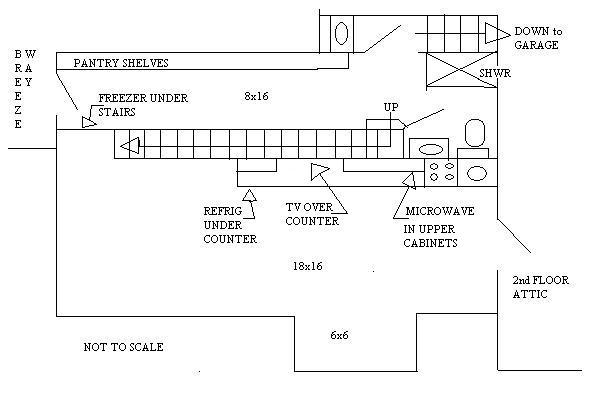

DECEMBER 2008:

Sheetrock work is coming along and the bathroom is laid out; all plumbing

rough-in work is also finished. So, I thought I'd show the modified

1st floor plan of the pantry/entry/bath area:

About the only thing

that's changed from my earlier

original sketch of the GarageMahal footprint

is the bathroom/stairs layout. Because we decided to go with a full bath (shower), we

had to redo the stairway and bath footprint, moving my air

compressor and expanding the bath into the space it had earlier

occupied. I'll try to add

photos of the finished sheetrock as soon as the workers remove all

their scaffolding.

27

December 2008:

All the sheetrock is hung and the rough plumbing finished.

Now, we wait for the sheetrock finishers to do their thing.

The stove, microwave, under counter refrigerator and sink are all

ordered - white appliances all. And the cabinet maker is

stopping by next week to get his measurements. Here are photos

of the project as it is today:

|

|

|

|

|

|

|

|

Looking

into pantry area from breezeway entry. Door on angle is

entrance to full bath. |

Looking back at breezeway

entry and stairs. |

Looking up stairs at

landing onto studio apartment level. |

From center of studio

apartment, looking back at landing. |

Kitchenette area of studio

apartment. |

Large cathedral ceiling

dormer area of studio apartment. |

Here's a sketch

of the entire project - 1st & 2nd floor - layout (not to scale):

30

December 2008:

Sheetrock finishers came by today to taped the walls and make the

finished corners. Two of the doors (bathroom & to attic) are here, and the

custom exterior door between the new space and the garage will

arrive Tuesday. The refrigerator and microwave arrived

yesterday, and the stove/sink will be here Wednesday. The vent hood will take

another week before it arrives.

So, things are moving along. The next thing that happens is my

contractor will set the door between the studio apartment and the

unheated attic to keep heat in the apartment so the sheetrock mud will

dry. And the finishers will be back in a few days to do the

second layer of sheetrock mud over everything.

Here are photos of how it looks after today's work:

|

|

|

|

|

|

|

| From

breezeway looking through pantry to bathroom door |

Looking

up stairs to landing |

Looking

back out over top of landing and pantry |

Kitchenette

wall to right of previous photo |

West

wall with entrance to attic area |

Dormer

area |

East

wall that connects back to landing |

9

January 2009:

Doors are installed, and we spent some time outside repairing a leak

we found. Here are photos of the doors:

|

|

|

|

|

| Bathroom

Door |

Door

to garage. |

Looking

down from studio apartment landing at both doors |

Garage

door from garage side. New utility sink sitting in place where

its cabinet will be built. |

Door

from studio apartment to attic portion of 2nd floor. |

|