Simplified

Wheel Bearing Installation

As

of: 14 October 2003

As

of: 14 October 2003

Many of you have worried and worked for hours trying to get the right

combination of shims on the front wheel bearing spacers of your MG. Just

when you think you have it nailed, you find that the cotter pin hole can't be

lined up when the nut is torqued properly. Well, all your labors were for

nothing. Why does your MG, and maybe some other British cars, have the spacer

and shims when billions of other cars with front wheel bearings do not? The

answer is simple. You don't need them. You could tie the spacers on a string

and drag them around behind you and they'd do just as much good as they do in

that hub.

Nearly all other cars in the world have wheel bearing configurations exactly

like your MG, except, they have no spacer or shims. They say the shims are for

setting the bearing "float", but you get the same float with or

without the shims. With the shims you work to a torque spec, without them you

don't.

To

be in step with the rest of the world leave the spacer and shims out. Tighten

the nut good and snug, turn the wheel a half turn or so, loosen the nut, and

turn it right lightly until you feel it make contact. Wiggle the wheel and if

you feel any play or looseness tweak the nut a little tighter until that play

is gone. If the cotter pin hole doesn't line up back off to the first cut in

the nut that will. Some spindles have two cotter pin holes, one vertical and

one horizontal. Catch the closest one you can and insert the pin.

The

reason for tightening the nut and turning the wheel the first time is to press

any excess grease from between the rollers and the cup. When you back the nut

off and re-set it lightly there will be a slight float, but you won't feel it.

Sometimes you can after the car has been driven a few miles. Most cars have no

cuts on the nut, but have a "tin" nut with cuts for the cotter

pin that slips over the "real" nut. You have infinite

adjustment with them. My MGB is the only car I ever worked on that had shims

in there. No other car, trailer, tractor, or anything else had them, nor needs

them, and the bearing, spindle, and hub configuration is the same as an MGB.

The only cars I ever worked on that required a bearing float that you could

feel were '40s and early '50s Chevy's that had ball bearing front wheel

bearings. The shims in an MGB are overkill, I've never worked on even an

airplane that had them.

Those bearings are going to do exactly the same thing with or without the

shims. Those cones don't float on the spindle either way, the angles on the

bearings take care of that.

|

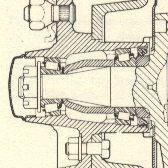

Look at this picture, study it a while,

think about it.

It all comes out the same with or without the shims, it's just

that the conventional way of adjusting them is much quicker and easier. The

taper on the bearings assure everything will work as it should, shims or no

shims, so long as the preload or float is adjusted properly. The key word

being properly, not precisely, this isn't rocket science you have a little

leeway. |

|

Knowing what you have just learned can save you a lot of time and toil the

next time you get into your front wheel bearings. Install the spacers and

shims if you simply must have it by "the book", but my book and

thousands of others don't have them.

John

Dandy

(theAutoist

NOTE: John Weimer's new "nom de plume")

|

![]() As

of: 14 October 2003

As

of: 14 October 2003 ![]()